The Ultimate Guide to Choosing Motion Control Systems

admin2024-06-14T02:50:50+00:00Motion control systems are at the heart of automation technology, enabling precision and efficiency in various industrial applications. These systems manage the movement of machines and are integral to manufacturing, robotics, and vehicle automation. Understanding motion control systems’ core functionalities and advantages is essential for any entity looking to enhance operational capabilities.

What Are the Basic Components of Motion Control Systems?

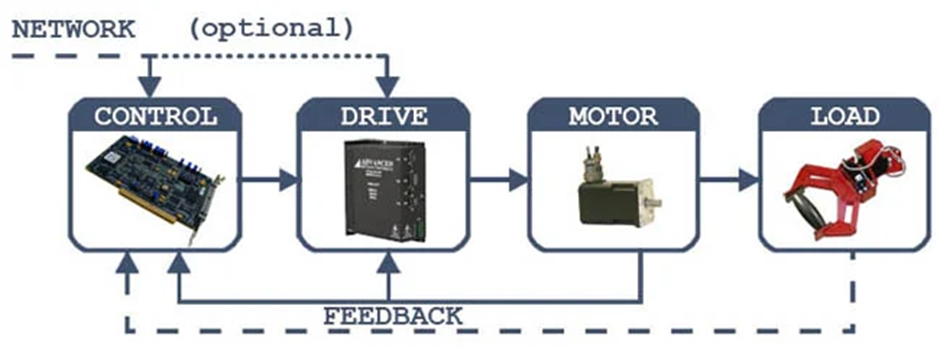

A typical motion control system consists of several key components, each playing a critical role in its operation:

- Motors: This are the actuators that create motion.

- Drives: Devices that power and control the motors.

- Servo Controllers: Units that direct the operation of the motor according to the desired process.

- Feedback Devices: Sensors that provide real-time data on the motor’s position, speed, and torque.

- Mechanical Components: Gears, belts, or screws that convert motor output into desired mechanical motion.

- These components work in concert to achieve precise and controlled motion within industrial systems.

How do motion control systems work?

The functionality of motion control systems unfolds across several stages:

- Initialization: The system powers up and initializes components.

- Command Reception: The controller receives the command specifying the desired motion.

- Action: The drive generates the appropriate power for the motors.

- Feedback Loop: Feedback devices constantly send data back to the controller ensuring the motion adheres strictly to the specified parameters.

Understanding Feedback Mechanisms

Feedback mechanisms are critical for real-time adjustments during operation, ensuring accuracy and consistency in the movement of the system.

The Role of Controllers in Motion Systems

Controllers interpret input commands and manage the hardware to execute precise movements, acting as the central decision-making units in motion control systems.

What Are the Different Types of Motion Control Systems?

Motion control systems vary widely, each suited to specific applications based on their operational principles and benefits:

- Open-loop Systems: Operate without feedback mechanisms, simpler but less accurate.

- Closed-loop Systems: Include feedback mechanisms for high precision and error correction.

- Hydraulic Systems: Use liquids to transmit power, ideal for heavy-duty applications.

- Electric Systems: Use electrical motors and are typically more precise and easy to control.

- Pneumatic Systems: Powered by compressed air, these are used for lighter, simpler tasks.

- Each system type comes with its own set of pros and cons, influencing its application based on cost, complexity, and control needs.

- robust enough to handle the operational stress without sacrificing performance.

Each system type comes with its own set of pros and cons, influencing their application based on cost, complexity, and control needs.

Hydraulic Motion Control Systems

Hydraulic systems are powerful and excel in applications requiring significant force and where precision is less critical.

Electric Motion Control Systems

Electric systems offer high-precision control and are ideal for applications requiring exact movements and complex configurations.

Pneumatic Motion Control Systems

Pneumatic systems are favored for their simplicity and cost-effectiveness in applications where fine control of force and position is less critical.

What Are the Key Specifications to Look For in a Motion Control System?

Choosing the right system involves understanding several key specifications:

- Speed: How fast the system can operate.

- Accuracy: The precision with which the system can achieve the desired position.

- Torque: The rotational force the system can apply.

- Load Capacity: The maximum load the system can handle effectively.

How Does Load Affect System Choice?

The choice of a motion control system is heavily influenced by the load requirements, as systems need to be robust enough to handle the operational stress without sacrificing performance.

What Are the Speed Requirements for Different Applications?

Different applications require varying speeds to optimize performance and efficiency, influencing the choice of motors and drives.

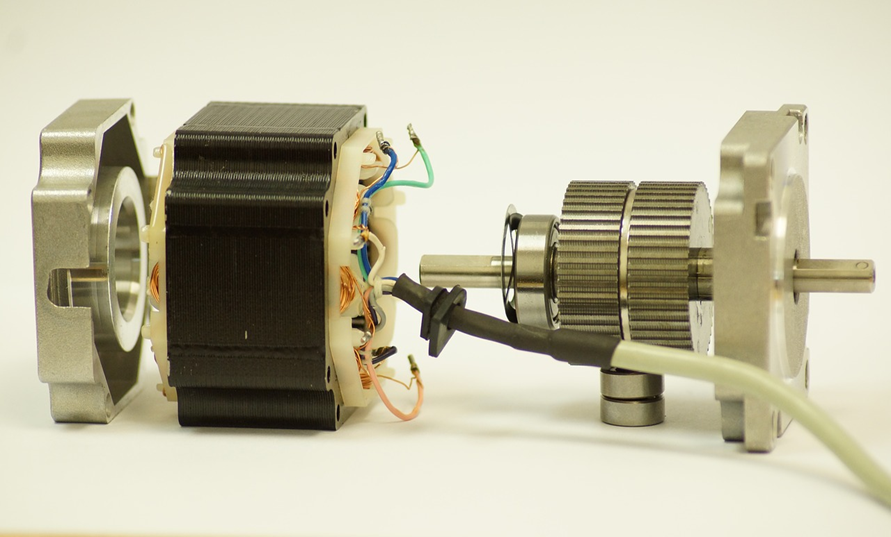

How to Choose the Right Motor for Your Motion Control System?

Selecting the right motor involves analysing the required torque, speed, and precision, ensuring that the motor’s specifications align with the application’s demands.

Comparing Stepper Motors and Servo Motors

- Stepper Motors: Offer precise positioning and are cost-effective for applications requiring simple, reliable motion.

- Servo Motors: Provide higher efficiency and better performance for applications needing dynamic, high-speed positioning.

What Are the Advantages of Using Advanced Motion Controllers?

Advanced motion controllers enhance system performance through:

- Improved Accuracy: Ensuring precise control over movements.

- Increased Production Speed: Optimizing operations for faster throughput.

- Flexibility in Control: Adapting to varying operational needs dynamically.

How to Integrate Motion Control Systems with Existing Machinery?

Integrating motion control systems into existing setups requires careful consideration of several factors to ensure compatibility and enhance overall efficiency.

Key Considerations for Retrofitting

When retrofitting, consider:

- Space: Whether there is adequate room for new components.

- Compatibility: How well new and existing components can work together.

- Cost: The financial implications of upgrading versus replacing equipment.

What Are the Common Challenges in Implementing Motion Control Systems?

Implementing these systems can be challenging due to:

- System Compatibility: Ensuring all components work cohesively.

- Complexity of Configuration: Setting up systems to function optimally.

- Cost Management: Balancing between performance needs and budget constraints.

Step-by-Step Guide to Selecting a Motion Control System

Choosing the right system involves:

- Defining Requirements: Clearly understanding what you need from the system.

- Evaluating Options: Comparing different systems and their capabilities.

- Vendor Selection: Choosing a vendor that offers the best support and product range.

- Testing and Implementation: Ensuring the system meets your needs before full integration.

How to Assess Your Motion Control Needs?

Evaluating your current and future needs helps in selecting a system that not only meets but exceeds performance expectations.

What to Consider During Vendor Selection?

When selecting a vendor, consider their:

- Support Services: The level of post-purchase support offered.

- Product Range: Whether they offer options that meet your specifications.

- Technical Expertise: Their ability to provide insights and solutions tailored to your needs.

What Industries Benefit Most from Advanced Motion Control?

Motion control systems are crucial in:

- Manufacturing: Enhancing precision and efficiency in production lines.

- Automotive: Improving the quality and speed of automotive assembly.

- Aerospace: Ensuring precise control in critical aerospace applications.

Step-by-Step Guide to Selecting a Motion Control System

Choosing the right system involves:

- Defining Requirements: Clearly understanding what you need from the system.

- Evaluating Options: Comparing different systems and their capabilities.

- Vendor Selection: Choosing a vendor that offers the best support and product range.

- Testing and Implementation: Ensuring the system meets your needs before full integration.

How to Assess Your Motion Control Needs?

Evaluating your current and future needs helps in selecting a system that not only meets but exceeds performance expectations.

What to Consider During Vendor Selection?

When selecting a vendor, consider their:

- Support Services: The level of post-purchase support offered.

- Product Range: Whether they offer options that meet your specifications.

- Technical Expertise: Their ability to provide insights and solutions tailored to your needs.

What Industries Benefit Most from Advanced Motion Control?

Motion control systems are crucial in:

- Manufacturing: Enhancing precision and efficiency in production lines.

- Automotive: Improving the quality and speed of automotive assembly.

- Aerospace: Ensuring precise control in critical aerospace applications.

Future Trends in Motion Control Technology

Emerging technologies such as AI and IoT are set to revolutionize the landscape of industrial automation by enhancing the intelligence and connectivity of motion control systems.

Conclusion

Choosing the right motion control system is crucial for enhancing operational efficiency and precision. By understanding the various types of systems, their components, and how they integrate into existing setups, businesses can make informed decisions that significantly impact their operational success.

Leave a Reply